News Blog

Today’s news briefs contain equal measures of dire warnings and exciting developments in the field of AI. Yet, while any technology should be treated with care — with great power comes great responsibility, as Spiderman’s uncle famously said — it is imperative for humanity to make the most of these cutting-edge innovations for the betterment of all.

Experts estimate that the global robotics market, which is currently worth nearly USD $32 billion, will be worth a whopping USD $190.8 billion by 2035. There is a lot of untapped potential, and Canadian tech companies are leading the way in developing new applications for multiple industries. Read on to discover the impact robotics is having and will yet have on the healthcare, manufacturing, and logistics industries, among others.

Robotics is no longer the future — it’s the present. From manufacturing to healthcare, logistics to energy, industries are integrating robotics at record speed, creating a massive demand for skilled technicians. The GBC Tech Training Online Robotics Technician Certificate Program is a launchpad into this high-tech, high-growth field. And our Graduates are pushing boundaries in manufacturing, automation, and tech-driven industries. They’re designing, programming, and maintaining robotic systems that increase efficiency and reliability in real-world operations.

Robots do dirty, difficult, and dangerous jobs. From welding and painting car bodies to applying adhesives, packing candies and loading pallets, they help manufacturers reduce waste and become more productive.

Every industrial robot has a drive system that generates the movements needed. Understanding the differences between these systems is key to successful selection and integration. This article introduces the three drive technologies used, highlights their strengths, and describes where each is used.

Industries ranging from manufacturing and food production to logistics and life sciences increasingly rely on industrial robots. These complex machines help them address labour shortages, protect workers from dull and dangerous jobs, and boost productivity. A limitation though, is that they’re not easy to implement and use, so the skills of a qualified robotic technician are needed to maximize the ROI from every project.

Industrial robotics, as a concept, is one that is understood by a large swath of the population. Rather than relying on dozens or hundreds of human workers to perform repetitive tasks along an assembly line, sophisticated robotics are leveraged to perform the same tasks in less time and with greater accuracy.

What many fail to realize however, is just how much goes into ensuring industrial robotics can properly execute the various actions they are required to perform. This is where rotational position control comes in and what makes industrial robotics possible.

There’s arguably no other industry that has changed more in the last couple decades than the manufacturing industry. Everything - from SCADA systems, wireless sensors, and articulated autonomous robots - has experienced considerable evolution, all to the benefit of manufacturers the world over. The resulting expansion of operations is intrinsically tied to the manner in which communications and controls are performed throughout the facility - enter Wireless Local Area Networks.

With tax season quickly approaching, it’s time to start preparing and gathering all relevant receipts and paperwork to file your taxes! GBC Technical Training students whose tuition fees have totaled at least $100 are eligible to receive a tax credit for tuition fees through the Tuition and Enrolment Certificate (T2202). Students can access and download their T2202 form from their online student account, which will account for all programs paid for during this calendar year.

An official transcript is a record of the grades you’ve earned while attending college.

It wasn’t that long ago that performing regular preventative maintenance was the best and only way of ensuring a fleet of expensive industrial robotics remained in good operating condition. Fortunately, this is no longer the case, thanks in part to the integration of AI technologies and data analytics.

With the holiday season quickly approaching, we wanted to update you on how the holiday break will impact our GBCTechTraining technical, tutorial, and administrative support.

Office Hours

The Student Support Center will be closed on Friday, December 22 at 5:00 p.m. and will re-open on Wednesday, January 3rd, 2024.

While technology continues to evolve by leaps and bounds, the number of workers with specialized skills seems to be trending in the opposite direction. And while robotics and automation are widely known to create jobs, many of them require specialized training - further exacerbating the shortage of specialists.

The applications of industrial robotics are as varied as the industries that use them. Defining said applications can be an arduous, if not impossible, task. And while many of those applications involve the use of highly sophisticated components and technologies – many of which will forever remain unknown to the layperson – it’s nearly impossible to think of industrial robotics without conjuring images of the mechanical appendages that have made robotics such an integral part of our world.

As the fields of robotics and automation grow ever more sophisticated, a greater number of technicians are required to lend their talents to the design, programming, and maintenance of robots and robotic automation systems. Not surprisingly, the complexity of these machines and autonomous systems has spawned five specialized areas within the field of robotics:

With the holiday season quickly approaching, we wanted to update you on how the holiday break will impact our GBCTechTraining technical, tutorial, and administrative support.

Office Hours

The Student Support Center will be closed from Friday, December 23, 2022, to Monday, January 2, 2023.

Imagine that you’re working on a project and you’re given the ability to know all the risks involved, the possible challenges that you’ll face, and the ability to sidestep both. Oh, and you’ll also save on production costs and delivery time.

By using a robot simulator, you’ll be able to efficiently and accurately utilize robots in your career.

Robots have become an essential element of the industrial production process, taking over repetitive, risky, and time-consuming work from people while simultaneously increasing productivity and quality. Technical breakthroughs and new inventive robots are quicker, more compact, and less expensive than earlier models. As a result, robots are now widely utilized in a variety of sectors like health care, agriculture, military, transport, and manufacturing.

If we were to compare computers to brains, then servomechanisms would be the muscles that do all the grunt work. Servomechanisms, sometimes shortened to servo, are an automatic device that correct the action of certain mechanisms by using error-sensors. When a servomechanism receives negative feedback, they’re able to course-correct the action.

As the landscape of manufacturing changes, with plant operations becoming increasingly automated, more technically skilled workers are required to maintain your company’s competitive edge.

With winter break quickly approaching, we wanted to update you on how the holiday break will impact our technical, tutorial, and administrative support.

Office Hours

George Brown College will be closed from Friday, December 24, 2021, to Tuesday, January 4, 2022. We won't be able to speak with you during this time but we are monitoring and responding to email inquiries.

Interested in learning more about the advantages of robots in manufacturing? You’ll want to keep reading.

Imagine working on a job that poses a serious risk to your health and safety—perhaps carrying close to 10 pounds of weight 350 times a day. Or imagine having to repeat the same mundane task over and over again when you could be doing something more interactive. This is why cobots, or “collaborative robots,” are leading the charge in manufacturing and taking over repetitive, even risky, tasks.

If you’re interested in getting started in the field of robotics, then chances are you’ve heard about robotic control systems. Control systems have a rich and fascinating history and have allowed robotics to become ubiquitous in today’s society.

Control systems help manage the movements and functions of robots, and every beginner must understand the concept of control systems if they would like to get into the field of robotics. Let’s take a look at the history of control system applications in robotics, the concept of the systems, and how they’re used today.

The recent challenges our world has been facing has provided an opportunity for robotics to become more involved in every aspect of automation. The pandemic, coupled with the increasing need to reduce carbon footprints, has shown how robots are changing the workforce and traditional work process. On top of that, the ongoing stresses being applied to global supply chains and workforce shortages have become a concern.

If you’re in a robotics technician training program and are curious about what will happen after you graduate, this article is for you.

GBCtechtraining has introduced chatbots into our websites over the last three years. The purpose of these chatbots is to help prospective students find information about our programs in a convenient and easy way. We are happy to report that our chatbots are heavily used and relied on by students around the world, particularly after regular office hours, and coming to us from far away time zones.

Here is a bit of helpful information and a few tips about our chatbots to ensure that you get the most benefit from them.

The potential that smart factories have to completely transform our world cannot be understated. With advancements in artificial intelligence and computer learning, manufacturers are increasingly turning their attention to the benefits of implementing smart factories within their plants. While the concept of a smart factory is not new, there are still some manufacturers who are slow to jump on the trend due to a variety of reasons, but especially because of the recent global pandemic that brought the world to a standstill.

Here at GBCTechTraining, we promote and encourage student success and we want to ensure that our students receive the necessary support when it comes to pursuing their studies. Our Student Resource Center provides a wide range of resources such as editing and viewing account information, viewing grades, taking exams, engaging in student forums, getting support from our staff and accessing additional learning material.

You might be hoping to advance your career in manufacturing or want to get into a new field of work and need technical training, yet your fixed schedule cannot fit into the timetable of many training programs. If this resonates with you, consider training that can be worked into your schedule.

“Winona” was facing a unique problem. She has been working as the Director of Sales and Operations of a local retail chain. They just launched their e-commerce site and because orders are flowing in, they have acquired two new fulfillment centers in the suburbs. Workers were divided into three shifts: preparing, packaging, and delivering customer orders from 6AM – 12AM. With the pandemic and resulting lockdowns, Winona had a dwindling workforce, but still saw a steep rise in online orders. Additionally, she was now faced with the task of implementing new safety measure protocols.

Robots have been a fascination in our society, dominating pop culture through TV and movies for decades. But it’s likely that the general population is only vaguely aware of industrial robots and the global brands that manufacture them.

The majority would be surprised to find out that the top industrial robots are dominated by four major brands: FANUC, KUKA, ABB, and Yaskawa Electric. All of these companies have been in operation for at least 40 years and have distinct advantages over the other.

Looking for new training opportunities but you aren’t sure which type of education would suit your needs best? Confused about the different types of education that are being offered and not sure what their differences are? Depending on whether you are looking to get into a new area of study or whether you want to advance your career by adding other credentials, all four options below can be useful. Check out the infographic below to see the differences between a Certification, a Certificate, a Diploma and an Associate’s Degree.

Robots have been growing in use in the industrial world since the early 1970s. They’re continuing to be deployed and utilized within the industrial sector, but also increasingly in other sectors as 2021 continues. The crisis brought on by the COVID-19 pandemic, coupled with the increasing need to reduce overall carbon footprints, has pushed robotics even further beyond traditional uses within manufacturing environments.

1. Fourth Industrial Revolution or Industry 4.0

The Fourth Industrial Revolution, or often referred to as Industry 4.0, is currently underway in all aspects of the global economy. Industry 4.0 represents the ongoing automation of both the traditional manufacturing processes and other industrial practices across non-manufacturing sectors of the economy.

In recent years, we’ve grown accustomed to the integration of smart technologies into our everyday lives. For manufacturing and industrial practices, this ongoing automation using modern smart technologies is referred to as the Fourth Industrial Revolution aka. Industry 4.0.

The continued adoption of industrial robots and cobots (collaborative robots) to work alongside humans in smart factories around the globe is a good sign that the robotic revolution is heading in the right direction. As engineers and designers seek to improve upon the autonomous actions that can be performed by robots (for example, being able to adjust their path to avoid obstacles in real time), there is also an undeniable need to elevate the level of safety standards that are required in places where the paths of humans and robots intersect.

If you’re considering taking one of our online technical training certificate programs, maybe you’ve been wondering what kind of a computer you need to install our program curriculum and simulation software.

Luckily, the technical requirements are modest, so most computers will meet them.

The three system requirements are:

Keeping up with the technology changes in the manufacturing/industrial industry is important to stay relevant in your job/career. With the world changing so quickly, it’s always a good idea to stay in the loop and know what the current and future trends are, and take advantage of opportunities to grow. But how can one keep up with the industry?

Below are 4 ways to stay up to date:

Autonomous vehicles, once relegated to works of science fiction and, more recently, among the technologies that “weren’t quite there yet”, are actually becoming a much more common sight – and not just on the test tracks used by large auto manufacturers. Autonomous, self-driving vehicles are quickly making themselves a fixture of the smart factory floor in a way that is revolutionizing operations.

The Fourth Industrial Revolution, or Industry 4.0, is constantly and rapidly evolving. New technological advancements in industrial smart factories seem to be happening all the time. This article will take a look at some of the biggest current tech trends in industrial manufacturing.

Advancements in technology are largely an iterative process, whereby design teams build upon last year’s breakthroughs to improve a product’s functionality, efficiency, and/or to lower its cost of production. The field of robotics is no exception; today’s robots are faster, more dexterous, are cheaper to produce, and work more collaboratively and intuitively with human operators than those built ten or even 5 years ago. It is therefore really no surprise that industrial manufacturers are pivoting towards having a more significant robotic presence on the factory floor.

STU-VIEW, George Brown College’s on-line Student Information System, is a web-based portal to the College’s database

As a GBCTechTraining Technical Certificate student your STU-VIEW account is the place to access;

Robotic technology combined with artificial intelligence (AI)-powered applications are working together to help policymakers, manufacturers, and key industry stakeholders manage and even reduce their carbon footprints. In fact, according to PwC and Microsoft, AI is projected to reduce global greenhouse gas emissions by four per cent in 2030, which is equivalent to 2.4 gigatons of carbon dioxide emissions.

Your home should be a stress-free environment. But living through a pandemic and the rules associated with it, can be more challenging especially since work and school are now more closely integrated in your home. If you’re working from home, attending online school from home, and managing a family, you may find that juggling all the different parts can be stressful. We often don’t realize that the line between work, study and personal time can get blurred; and to some extent the pandemic has made it more difficult to find that healthy balance between work, school and play.

Industrial robots are all around us; they produce the goods we consume and the vehicles we drive. To many, these technologies are often viewed as simplistic in nature. After all, while they are uniquely capable of producing products quickly and at a high level of quality, they operate within a limited range of motions. So just how much really goes into programming an industrial robot?

Did you know that typically only about 40% of students actually complete their college certificate or degree, (after a period of 6 years)?[1] That’s a stat that most schools aren’t too comfortable talking about but the reality is that getting through a postsecondary program is really a tough challenge. And I’ll add that distance education, self-paced learning programs, like ours, are typically even lower.

The COVID-19 pandemic is creating new challenges for the manufacturing industry. Research by the United Nations Conference on Trade and Development (UNCTAD), estimates that the COVID-19 outbreak could cause global Foreign Direct Investment (FDI) to shrink by 5%-15%, due to the downfall in the manufacturing sector. Across the globe, automobile, chemical, electronics, and aircraft manufacturers are facing shutdowns and inaccessibility of raw materials.

If you are a first-time online learner, taking an online course or even considering one you may find that they can present some unique challenges. Without a plan for managing these challenges, your performance could suffer. Here are 5 tips to help you succeed in an online class.

The holiday season is almost here, and we wanted to update you on how the holiday break will impact our technical, tutorial, and administrative support.

Office Hours

The Student Support Center itself will close at 10 pm on Wednesday December 23, 2020, and will reopen on Tuesday morning, January 5, 2021.

Registration

The beginning of this, the third decade of the new millennium, may have started out rather bleak, but it does not mean that things like innovation or advances in technology have come to a grinding halt. In fact, quite the opposite is true. As we find ourselves in the midst of the Fourth Industrial Revolution (more commonly referred to as Industry 4.0) the adoption of automated machinery in the manufacturing sector shows no indication of slowing down.

Online education has brought numerous advantages to learning, such as making education more accessible, and in some ways, more interactive and engaging. However, it has also brought some unique challenges. Feelings of isolation, difficulties with self-direction as well as time management issues are common among students in online courses. Students may feel isolated if there aren’t resources or opportunities available to interact with faculty or other students.

Online programs can be a challenge for students, especially when the lack of in-person interaction is paired with learning new and unfamiliar technology. Our team has worked hard on creating a number of platforms and tools to help students become a part of the community, build professional relationships, and discover job opportunities. You can access all of this through our private Facebook group.

Here are 3 reasons why you should join if you’re a registered GBCTechTraining student:

As we are still in the middle of a pandemic, many post-secondary institutions have shifted their traditional in-class instruction and delivery of programs and courses online. Our programs have always been delivered online, and we have the resources and services to help support your success through your studies. Whether it’s looking for technical support or downloading your eCertificates, you may need to access various resources and services from time to time. Below are 6 specific ways we can help in our online program.

As Covid-19 is brought under control, many people are anxious to get back to work. While some may be able to work from home, it is important that safety measures are in place for those who must physically return to their workplaces. The manufacturing industry must have measures in place to prevent the potential spread of the virus as technicians return to warehouses, factories, and other workplaces. Let us review a few new technologies and procedural changes employers can implement to ensure that their spaces are safe for returning technicians and visitors.

In a 2018 study by Deloitte and the Manufacturing Institute it was predicted that by 2028 there would be in excess of two million unfilled positions in manufacturing—a deficit created by what is being called the “Manufacturing Skills Gap.” The changing landscape of the manufacturing industry, paired with an outdated reputation and quickly developing technology, has created this gap between the skills that manufact

Since March, the GBCTechTraining team has seen a number of changes to our processes, due to the Covid-19 pandemic. We have had to rethink the ways that a number of our resources are delivered, including how students access their program materials and documents. Physical materials and documents can no longer be sent out due to the closure of GBC’s physical location and mail room—so we have had to take these materials fully digital! Here are six ways that GBCTechTraining has updated and improved our processes since the beginning of Covi

In theatre, being a Triple Threat means that you can sing, dance, and act—that you have all the skills necessary to take on any role and succeed at it. This term can be applied to manufacturing, as well, and refer to someone who has skills in multiple disciplines, able to take on work in many departments.

Here at GBCTechTraining, we take student support very seriously. This means keeping track of the questions both current and prospective students ask regularly, anticipate potential questions, and make answers and information accessible to all. However, there are always questions that we may not foresee, but would love to answer!

Here at GBCTechtraining, we are very proud of our graduates. Their stories inspire us, and we hope they will inspire you as well!

This post highlights some of our graduates' experiences and gives some insight into how our online technical certificate programs have impacted their careers and lives. Take a look at how our graduates have found success after completing a GBCTechTraining program.

Covid-19 has made it difficult for even the most social among us to build connections. Here are a few tips to help technical professionals build and maintain their connections online, and prepare themselves for the post-pandemic world.

In today’s world, our lives are changing. From the way we interact with the environment, our friends and family, and even in the workplace. While the measures put into place due to Covid-19 are temporary, the pandemic will likely have a lasting impact on our lives.

Congratulations in taking that first big step to upgrade your skills by registering into the Robotics Certificate program. Now that you have signed-up for the program, you should have received an email with a link to download the web-based curriculum software. This means that once you have installed the program material (simulation software and web-based curriculum software) onto your computer you can start learning immediately.

Covid19 has brought with it a number of changes, with social distancing and work-from-home measures becoming common. At GBCTechTraining, these changes mean that while our online programs are still available, George Brown College has closed its physical buildings to staff and students and we are working remotely. Due to this closure we are currently unable to mail out Certificates; but not to worry, you are now able to access your Certificate as an online eCertificate.

George Brown College Technical Training is proud to present an updated version of the Robotics Technician online certificate program. The program provides a basic introduction to the theory and practice of using industrial robots in manufacturing.

The COVID-19 pandemic and our government’s public health and societal response to it are having a dramatic effect on all of our lives, and the way we interact with each other as individuals, businesses and public institutions. George Brown College and our distance learning department have been challenged to adapt and adjust the delivery of our programs. This includes the way we provide our services to our students in this new normal. The good news is that the GBCtechtraining programs and services are fully operational, open to new student registrations, and here to support you.

Students often think that once they gain technical knowledge, they are ready to go and get that career they've always wanted. They often overlook the soft skills, thinking that they're something that we're all naturally good at (or not).

The image we carry in our minds about what robotics and Artificial Intelligence (AI) are is usually polarized. For many people, what we think of robots is likely influenced by popular culture; movies, books or comics. Many people imagine robots like Star Wars droids or Pixar’s Wall-E or at the other end of the spectrum something like the humanoid AI-enabled robot virtually indistinguishable from humans from the movie Ex-Machina. Some tend to underestimate their capabilities and consider them fancy gadgets.

Modern robots perhaps aren’t what we envisioned they would be fifty, thirty, or even ten years ago. Robotic butlers don’t greet our guests, prepare our meals, or drive us to and from work (yet). Despite this, robots have had a substantial and undeniable impact on each and every one of our lives.

For decades, robots and sophisticated automation and control systems were relegated to the likes of large manufacturers, such as Boeing, GM and Procter & Gamble.

Over the years, we’ve had many questions about the certificate that graduates receive upon completion of a George Brown College online Technical Training Certificate program. We often get questions about what it looks like, its value, the accreditation it carries, and how it prepares you for a career in the industry.

With the rise of industrial automation comes the demand for skilled workers that are able to work, troubleshoot, repair, program, and maintain these new machines and technologies. Robotics engineers and technicians are some of the challenging and exciting roles that have come from this evolving trend of automation and use of robots in manufacturing. Robotics technicians are responsible for servicing robots by building, maintaining, programming, and repairing them to ensure optimal machine performance throughout the machine’s lifetime.

The beginnings of automation brought both ripples and tidal waves of change throughout the manufacturing industry over the past few decades. As the world enters into a fourth industrial age – one characterized by ubiquitous digitization and connectivity – many trade workers have expressed their fear of further automation, especially given recent reports of widespread job losses that continue to perpetuate this fear. However, automation could actually be a big upside for employee growth, especially for those who wield the right skills.

With tax season quickly approaching, it’s time to start preparing and gathering all relevant receipts and paperwork to file your taxes! GBC Technical Training students whose tuition fees have totaled at least $100 are eligible to receive a tax credit for tuition fees through the Tuition, Education and Textbook Amounts Certificate (T2202A).

Real-world robots are still very clumsy but this is changing fast.

Two commonly misunderstood types of training are certificates and certifications. Both provide important value, but are quite different in terms of purpose, content, oversight and commitment required to complete them. Selecting the right training will ultimately increase your hire ability and/or value to your employer.

As more self-driving cars hit the streets, there will also be more self-driving vehicles on factory floors. According to a 2018 study from PwC and The Manufacturing Institute, 9 percent of manufacturers use semi-autonomous or autonomous vehicles within their operations today; this number is expected to climb up to 20 percent in the next three years.

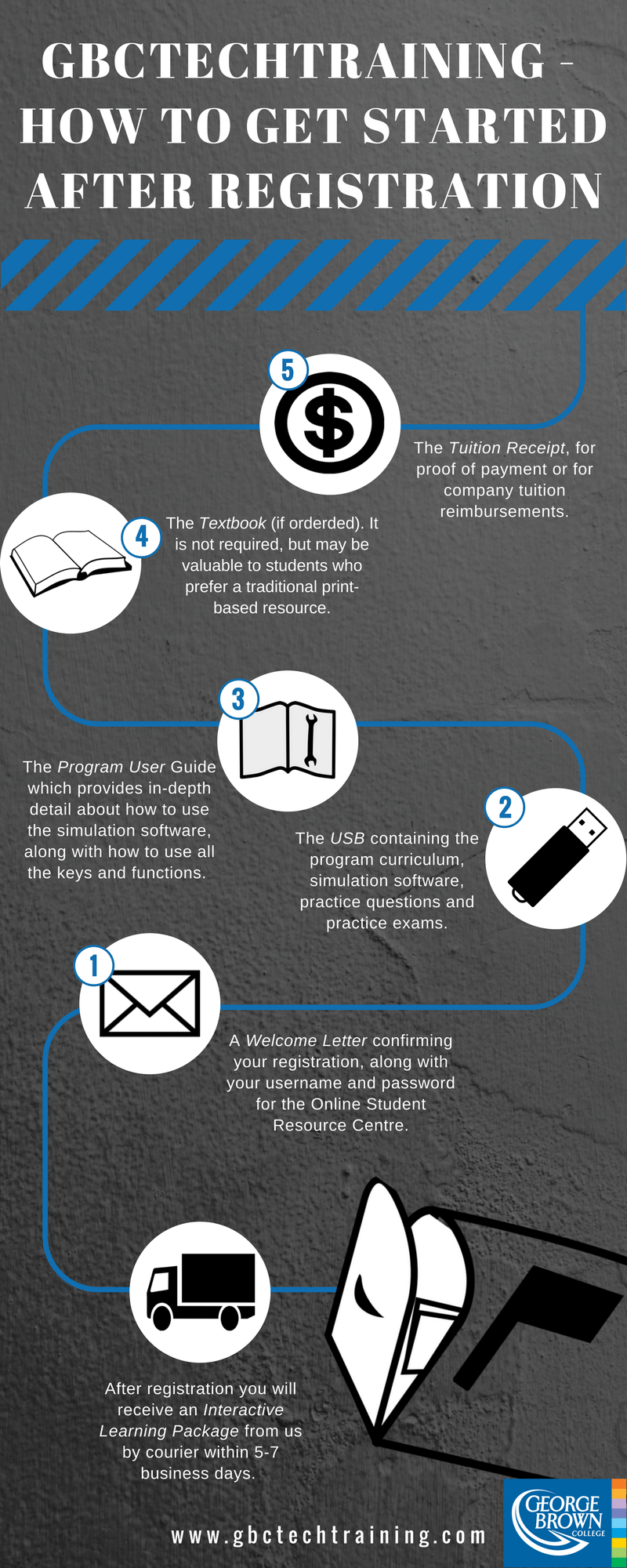

Here is a brief description of what you will receive upon registration into either the Automation, Robotics, Electromechanical, Electronics, or PLC programs.

The US has revolutionized the manufacturing industry with its numerous contributions, such as introducing the assembly line. But in today’s industries, it’s falling behind. Robotic technology for automation continues to develop at a rapid pace—and the US manufacturing industry needs to catch up. Here are five reasons why US manufacturers need to invest in automation more than ever.

The world of manufacturing is drastically changing. New technologies are leading to what analysts describe as the fourth industrial revolution, otherwise known as Industry 4.0, a term that was introduced at the Hannover Fair in 2012 by German workers. The fourth industrial revolution is marked by the introduction of disruptive technologies, where machines and robots can make decisions and perform tasks on their own without human intervention in an autonomous system.

Manufacturing is experiencing a renaissance in North America, but manufacturers regularly report difficulty filling open positions. If you aren't sure a manufacturing job is for you, check out our debunking 5 myths about manufacturing jobs infographic to see why there has never been a better time to enter this dynamic field.

We’re already living in the future where machines mimic cognitive functions that are associated with humans. These machines, also known as artificial intelligence (AI), are transforming industries and the workforce. Despite growing concerns that AI are replacing our jobs, it’s actually transforming the way we work by freeing our time so we can focus on other things. Here’s five ways AI is improving the way we work.

Voice controlled speakers such as Amazon Echo and Google Home are currently the biggest voice assistants in the market, and are part of the household trend in smart home devices. These smart devices enable people to retrieve information, dim their lights, or play music tracks by speaking their wishes.

With the most recent advancements in voice-controlled technology and robotics, these devices will soon be performing other tasks that are more labour intensive—such as doing your housework.

As companies such as Tesla and Uber continue to make progress in their plans to take over the automation industry with unmanned vehicles, we're living in a world where everything is becoming more automated. For instance, although trains have been semi-automated since the 1960s, recent technological developments have led to driverless train, as seen in Kobe, Japan and Lille, France.

Completely negotiate viral e-tailers and 2.0 platforms. Collaboratively deliver excellent mindshare vis-a-vis resource sucking paradigms. Dynamically maximize vertical architectures without real-time metrics. Assertively transform holistic scenarios for client-focused bandwidth. Rapidiously seize enabled partnerships and excellent supply chains.

There are many countries around the world experiencing an aging and declining population and low birth rate. Its expected that these countries will increasingly rely on technology and automation to complete tasks which were once done by people. This is especially true when looking at the medial care sector. With an aging population and fewer numbers in the younger generations there is an expected strain on personnel, which a few countries are already experiencing.

Automation has been making headlines in recent years, as technological advances have led to the creation of some pretty impressive gizmos and gadgets that can handle a myriad of tasks that were once dependant on human labour and creativity. From writing news to escorting patients to a waiting room, modern day robots are clearly capable of many tasks that were once the stuff of movies and dreams.

When we think of robots and automation, we often think of Japan and the US: highly advanced societies with a huge amount of focus on technological solutions to problems. And it’s true that the presence of robots in Japan – and increasingly so in the US as well – is ubiquitous and growing fast as the manufacturing world moves ever onward to greater automation. However, other countries aren’t far behind, and there’s a possibility that the next big user and consumer of robotic technology might not be the US or Japan at all, but Mexico.

Robots on the Rise

Hundreds of thousands of people working in warehouse type settings within North America use pallets to stack and organize their products daily. Pallets have become rather synonymous with warehouses; their utility and necessity cannot be argued. Pallets allow us to easily transport large and heavy amounts of product from the assembly lines, to the shipping area, and then to to customers.

Robots are continuing their unstoppable march into previously unheard-of sectors. Why should the restaurant industry be any exception?

Automated Kitchens

A completely automated kitchen might sound like something straight out of science fiction, but it’s actually closer to reality than you might think. Last July, the German-developed BratWurst Bot served, cooked, and took orders for over 200 meals to guests at a garden party, many of whom were surprised to learn that robots were capable of such tasks.

Milk production on dairy farms has used large amounts of automation for many decades, and cheese production is poised to follow suit. For decades, many industries have turned to automation to boost productivity, and the food processing industry is joining the fold. The use of robots makes food supplies and factories safer by reducing the potential for human error and the spread of diseases.

Modern Automation in the Cheese and Dairy Industry

Developing a curriculum that places heavy emphasis on robotic technology can no longer be considered just another niche educational supplement designed to promote an interest in STEM subjects in today’s youth. Increasingly, such programs are being recognized as playing a vital role in providing the workforce of tomorrow with the skills necessary to thrive in an evolving, in-demand sector.

Employment Rates in North America: Are Better Times Ahead?

Satellites traveling in geosynchronous orbit around the earth are tasked with performing some of society’s most important services – everything from maintaining the integrity of the global telecommunications network to the monitoring of weather systems and the environment.

Programmable logic controllers, or PLCs, have long been considered as one of the pillars of the modern manufacturing era, unobtrusively executing the ladder-logic instructions necessary in industrial automated processes. While versatile, PLCs rarely work alone; things like servos, robotics, testing equipment, and vision systems can all commonly be found working in conjunction with PLCs in the manufacture of goods.

In the cinematic world, legions of robots capable of scaling walls is usually a cause for concern for the film’s protagonist. In the real world however, robots are being programmed to perform such feats in order to takeover some of society’s most dangerous or unpleasant jobs, not only saving lives in the process, but also saving companies in the energy sector thousands, if not millions of dollars.

When you think about all the complicated and dangerous tasks society could be using robots for in the not too distant future, what comes to mind? Will robots be used to pioneer deep space exploration to spare the fragile human body from the dangers of a frozen, irradiated void? Will robots replace human workers for things like search and rescue, fighting fires, or operating the oil platforms located in the middle of Earth’s most tumultuous seas?

Robots have been used in medicine since 2000 when the FDA first approved the da Vinci Surgical System. Sixteen years and 20,000 surgeries later, the concept of a robot performing surgery is not nearly as far-fetched as it seemed at the beginning of the century. Now the da Vinci system, and many others like it, perform surgeries every single day – and yet we are still only at the very beginning of the age of healthcare robotics.

In 2013, Amazon made headlines by announcing their plan for a drone delivery system. Although seemingly an amazing advance, the truth is that drone technology has come on in leaps and bounds over the last decade or so, and it was only a matter of time before someone decided to deploy them commercially. It’s a logical step: Amazon wants to stay ahead of the game and ensure that its reputation for fast, secure delivery isn’t compromised or overtaken by its competitors. Why not do something that nobody else was even thinking of?

Robots have often been thought of as the stuff of science fiction, but the truth is that robotic technology is quickly advancing and is becoming more and more useful in various situations. Already ubiquitous in manufacturing plants, robots are also becoming widely used for such applications as defusing explosives, remote surgery, and as companions for the elderly, particularly in Japan. But it is in disaster relief that the potential of robotic devices is really coming to the fore.