What kind of Industrial Robots are Used by Manufacturers today?

Interested in learning more about the advantages of robots in manufacturing? You’ll want to keep reading.

The world has experienced a few industrial revolutions, the latest of which is being called ‘Industry 4.0’. It encompasses recent trends of industrial automation, as well as the use and creation of Big Data. One of the most interesting changes to Industry 4.0 is the growing development and use of industrial robots. In this article, you'll read about the top 5 different kinds of industrial robots, each with their unique set of advantages and disadvantages, that can be found in a range of modern manufacturing environments today.

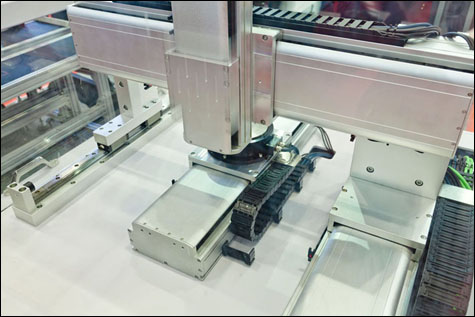

Cartesian Robots

Digitizing the factory floor is no easy feat so it’s no wonder that the Cartesian robot is one of the most popular robots used in manufacturing. It boasts three main linear axes of control, hence the name ‘Cartesian’.

Known for their ease of use and programmability, they’re a popular choice amongst plant operators looking for a robot that provides them with flexibility when it comes to implementing custom configurations. Their durability and the fact that a single controller is used to simultaneously control many of these robots also makes for a rather compelling set of advantages. While one drawback is the fact that the initial assembly process can be quite complex, the advantages it does provide continues to ensure the Cartesian robot’s success amongst manufacturers everywhere.

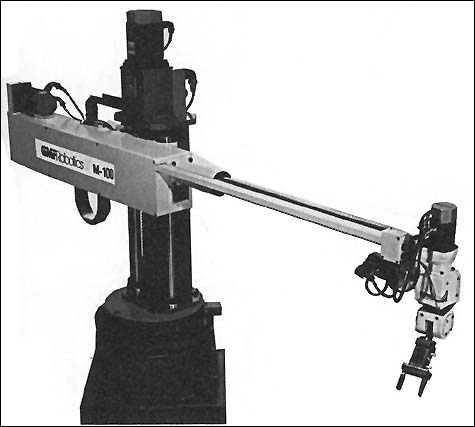

Cylindrical Robots

Image credit: https://www.industrial-electronics.com/industrial-electricity-com/4_Cylindrical_Robots.html

While Cartesian robots may be more common in manufacturing, Cylindrical robots are nearly just as popular and come with their own set of advantages. The typical Cylindrical robot features a rotary and a linear moving part, so they are a little more economical in terms of space than their Cartesian counterparts. They are also quite easy to use as they require less assembly and maintenance. Cylindrical robots are often used for assembly operations or spot welding, and they’re typically used in tight workspaces due to their compact design.

.

SCARA Robots

SCARA stands for Selective Compliance Assembly/Articulated Robot Arm. This type of robot has been found in manufacturing plants for a few decades now, now, due to their versatile range of motion and their ability to handle a variety of operations. SCARA robots have advantages and disadvantages. . They feature rotary motion in addition to being able to move along the x, y, and z planes. This makes them useful for many vertical assembly tasks and provides a speed advantage over Cartesian and Cylindrical robots.

However, when making use of SCARA robots, it’s important to consider factors such as load and environment. For instance, SCARA robots bear weight when their arms are extended. This means that too large a payload can result in reduced accuracy. They are, however, quite useful in environments with limited space as they tend to be quite compact.

Delta Robots

Image credit: https://industrial.omron.us/en/products/x-delta

Delta robots are often described as spider-like, as they feature a common base to which three jointed parallelogram-shaped arms are attached. It’s an efficient beast that operates like a human arm, moving items from plane to plane – however its influence is anything but biological.

While many tools opt to design tools based on natural influences, delta robots are purely geometrical and mathematical in design. They’re gaining popularity due to the fact that they can operate quickly, accurately and effectively without sacrificing load bearing capabilities. They are also quite flexible and have proven to be a favourite amongst manufacturers requiring pick-and-place features in a robot. That said, they are fairly expensive and are not necessarily a realistic choice for all manufacturers due to this very reason.

6-Axis Robots or Articulated Robots

Delta robots aren’t the only arm-like robots to grace the modern factory floor. 6-axis robots are also somewhat arm-like and can move along 6 different axes, as the name suggest. This means that they are able to carry out a wider variety of tasks than robots that feature fewer axes. Another advantage is that they come in a range of different sizes, ranging from toy-like to absolutely massive. However, programming the 6-axis robot can be somewhat complicated because they have to be designed with various types of rotary motion in three-dimensional space.

Stay Up-To-Date

As the world hurdles its way through Industry 4.0, robots of all kinds will continue to be integrated into manufacturing operations throughout North America in the coming years. As a manufacturing worker looking to keep up with recent progress, online robotics courses might prove to be an effective way to learn new skills required for the modern workplace. If you want to learn more about being a robotics technician or if you’re still considering the robotics program check out our Robotics Technician training program, available through online learning. Or contact us toll-free at 1 888-553-5333 or email us at info@gbctechtraining.com.